We ll discuss the various modes of heat transfer such as convection and how analyzing the distribution and stress caused by heat can help us make informed design decisions after completing.

Fusion 360 thermal simulation sheet metal issues.

Subscribe to autodesk virtual academy.

Autodesk fusion 360 allows us to analyze these thermal effects to help optimize any design.

Lesson 4 video part 1 5 zip 84 45 mb lesson 4 print guides zip 488 38 kb.

In this course we learn about the distribution transfer and stress on parts caused by heat.

The link below i.

Fusion 360 is the only tool to integrate design to manufacture.

When it comes time for testing there s a simulation environment with features such as static stress and thermal analysis.

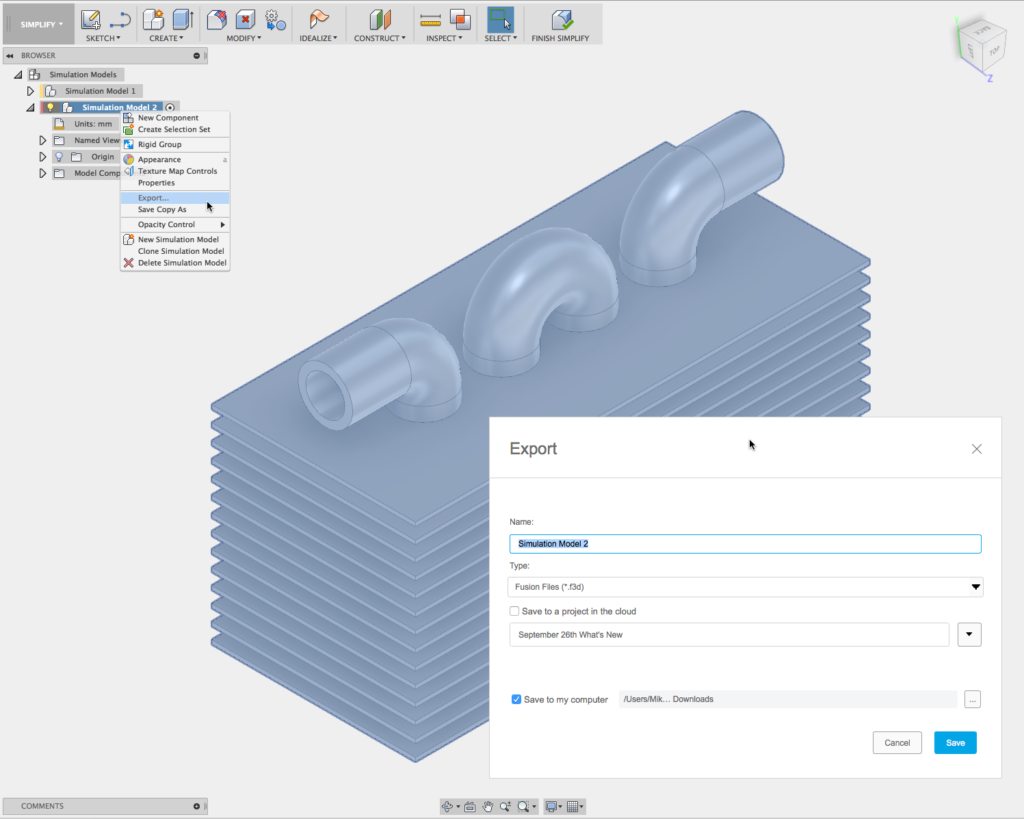

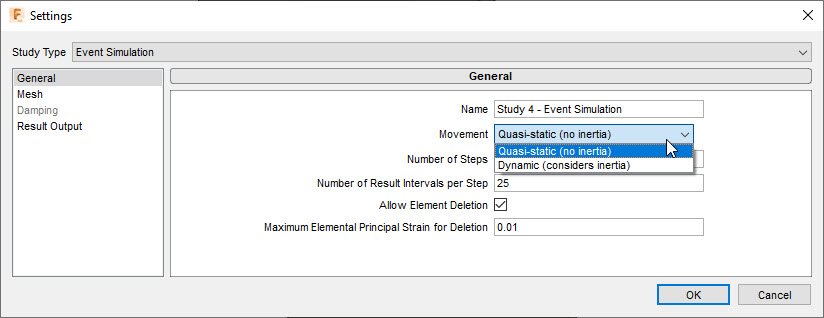

Cut solve time or explore design changes specific to the simulation workspace.

Let s show how to create sheet metal bends folds flange unfold flat pattern and more.

This video is a very quick overview of a setup for a thermal simulation in fusion 360.

Fusion 360 has released the sheet metal modeling environment.

We will get the simulation results such as temperature heat flux and thermal.

Aside from the standard modeling tools fusion 360 also includes environments for creating surfaces and sheet metal parts.

Here we are looking at the overall basics of a thermal analysis in fusion 360 simulations.

It s based on a question in the autodesk user forums.

Sheet metal in this lesson you use fusion 360 to create sheet metal parts based on default and custom rules through the use of sketching and feature tools.

In this lecture we cover a simple electronics example.

Now you get why fusion 360 s sheet metal is different.

Will elevated temps cause pr.

Fusion 360 makes a comprehensive set of tools available to the user.

Design sheet metal parts components document flat patterns using 2d drawings and dxfs and manufacture your design with cutting strategies for water jet laser and plasma machines.

Fusion 360 is superior in terms of its low price the possibility.